Ed. W

688

A visit to Hublot in Nyon: Judgements and redemptions

Hublot is a bit of a controversial name in horology, my opinion of the brand has fluctuated from great admiration in my mid teens (when the Big Bang was introduced and heavily advertised) to mild contempt after discovering their movements were 7750 based. My current attitude is that the brand has every right to sell a product that was in great demand, but it's still got a bit to prove. The brand is currently around 350 employees producing 35,000 pieces a year and growing rapidly.

I was fortunate enough to visit the Hublot manufacturer last week in Nyon, Vaud canton about 15 minutes by train outside Geneva. The current factory was built in 2009 but the company has already outgrown the building and purchased another building for expansion. All operations take place in the building including movement production (from raw material to the finished movements), casing up, and quality control. Hublot does not make its own cases with the exception of the new ceramic based Magic Gold, and also buys (like almost all manufacturers) its sapphire crystals, straps, jewels, and clasps.

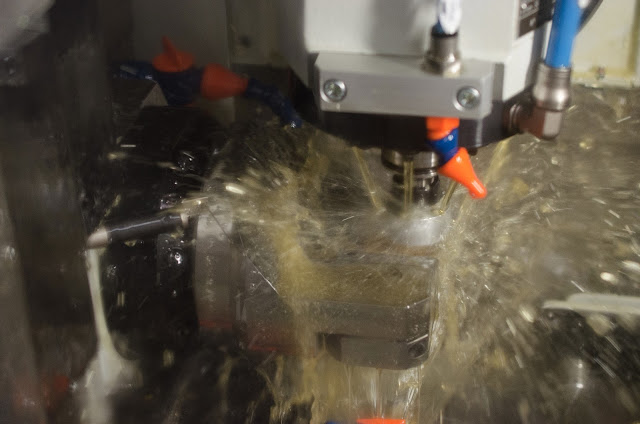

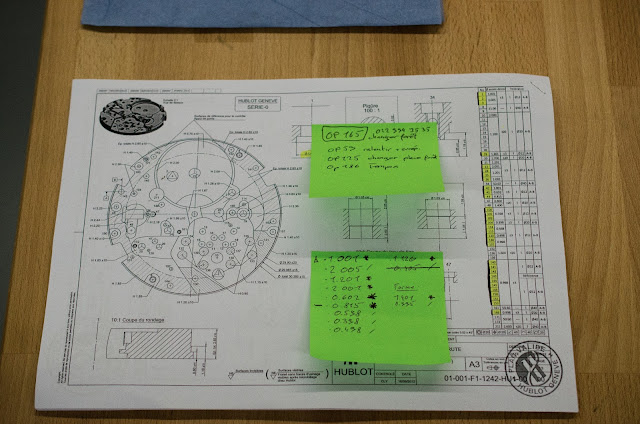

CNC machining of a mainplate

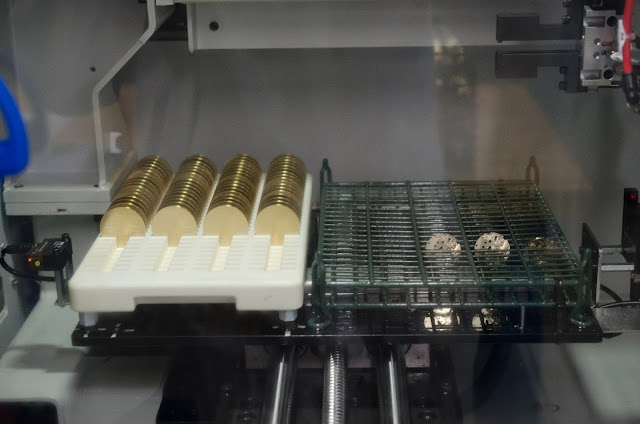

Machine mainplates, awaiting further treatment (finishing and plating)

Cut brass discs and complete mainplates

The first part of the building is filled with CNC machines and spark erosion machines used to produce watch parts. I did not notice any machines producing either small parts such as pinions and escapements or silicium parts but they could be elsewhere in the building, although my bet is that silicium parts are purchased from a supplier.

Steel parts made from wire-spark erosion

Parts made with wire-spark erosion (passing an ultra high voltage through an extremely thin metal wire)

The wire is the width of a human hair

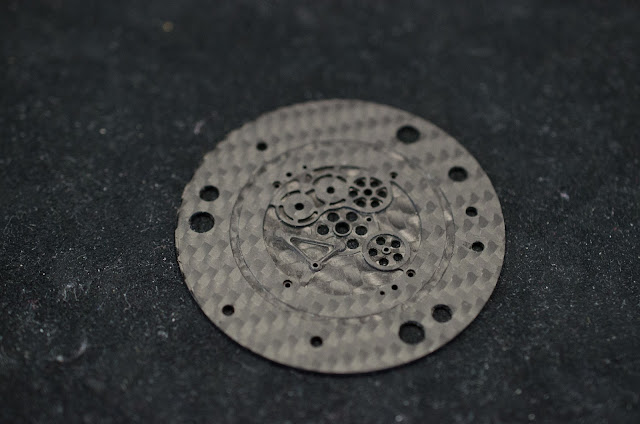

Since the brand focuses on "The art of fusion", many movement parts are made with carbon fiber and other novel materials.

Tucked in the back of the parts manufacture area is a room filled with autoclaves and other machines where Mr. Senad Hasanovic works on producing the new scratch resistant 18 karat magic gold, which is produced by making a ceramic tube that is 75% porous and then forcing pure gold into those spaces to produce 18k (750/1000) ceramic gold. The material behaves the same as ceramic, being extremely hard but slightly brittle. However, it appears like a dark gold alloy and is extremely dense. A new material, which could be named magic aluminium, will take the technique for magic gold but apply it to aluminium to produce a lightweight grey material.

Material engineer Mr. Senad Hasanovic explains the process of Magic Gold.

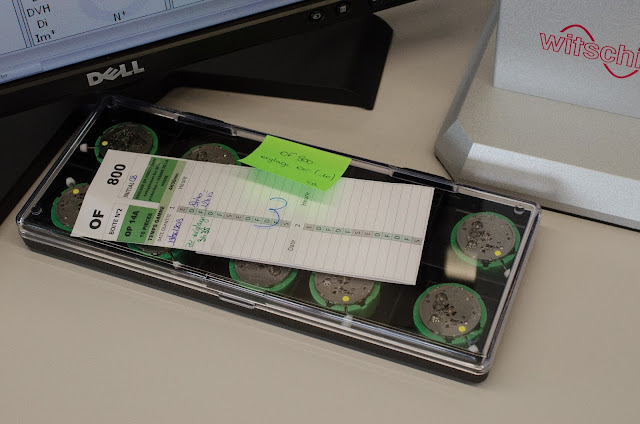

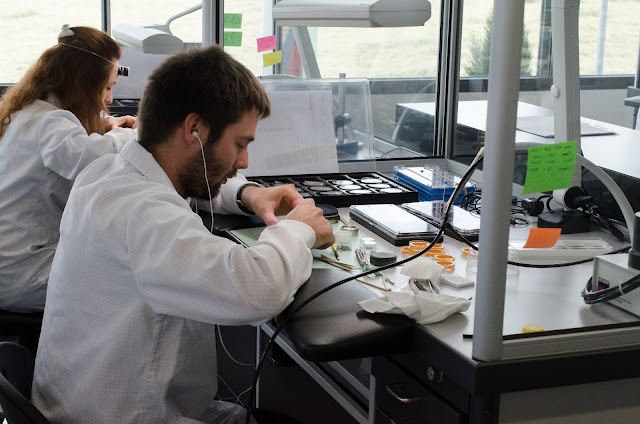

Preassembly involved a semi-automated placing of jewels and small posts into movement parts. The parts are QC'd before being brought to the assembly area where the final watch is assembled. There is a single workshop for producing the in-house UNICO chronograph movement which features a modular escapement with silicium anchor and escape wheel. The movement is not free spring but the brand is certainly aware of the demand for free sprung balances and we may expect to see one in the future.

Semi-automatic jeweling operation

The operator places the correct sized jewel in each sink and the machine places them on the part

QC of jewleing operation

Hand driving of jewels for more limited production movements

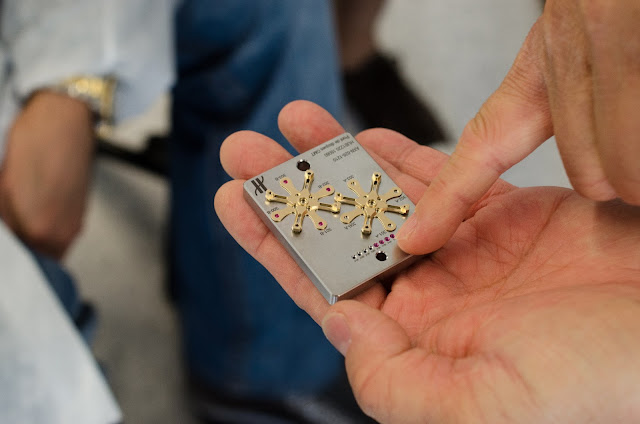

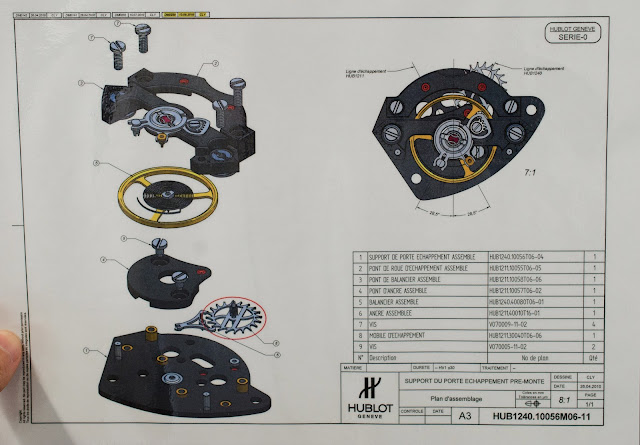

Diagram of the modular UNICO escapement

Purple silicium escape wheel with stylized "H" spokes

Silicium anchor of the Unico movement

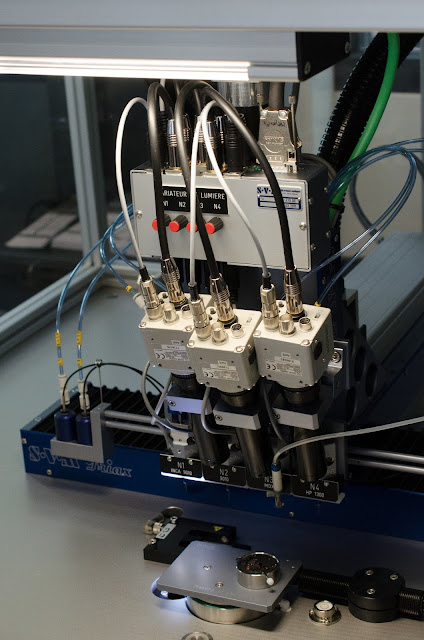

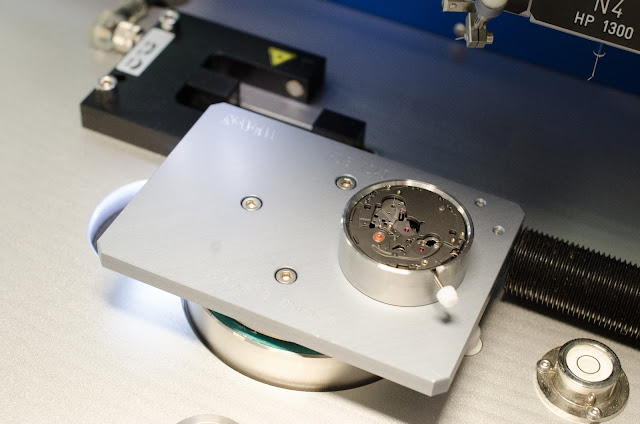

Automatic lubrication machine, applies the perfect quantity of oil on each oiling point

Grease for watch stems and a small pad for noting imperfections on watches

The haute horology workshop is in a separate area of the building where the brand's finest offerings are finished by hand and assembled by a single watchmaker. Two examples that I was shown are the skeleton tourbillon and minute repeater monopusher chronograph tourbillon.

Hand perlage in the haute horologerie workshop

Poising a balance wheel

Classic Fusion Skeleton Tourbillon Titanium

King Power Minute Repeater Chrono Tourbillon (48mm)

Despite being rather judgmental about the brand previously, it's understandable that the brand is rapidly growing and there is no reason why it could not eventually produce its own cases and all movement parts. Hublot certainly knows its customers, and how to get even more, and that's an admirable quality in and of itself.

I'd like to acknowledge Edouard Elias of Hublot and our Hublot moderator Ken (KIH) for this opportunity to learn about the brand.

A visit to Hublot in Nyon: Judgements and redemptions

Great report!

Thanks for the compliment Ken, wouldn't have been possible

HQ report.

Indeed, it's better than just watching the selective

WOW.... Awesome post.

Thanks doc.

Thanks a lot Ed for this great report!

Nice report Ed

Thanks Ed. Manufacture...hey! .....

Thanks for English lesson...

English lesson? Did I give an English lesson????

Just to be clear, I am not the one making war.

Regarding tools